As construction projects become larger and more complex, reducing environmental impact while staying efficient is now a top priority. This highlights the importance of fabrication in the AEC industry.

From offsite construction to modular parts, fabrication supports smarter and more cost-effective ways to build.

In this blog, we explore how fabrication supports sustainable growth in architecture, construction, and engineering. This can help your business stay competitive and create a better future.

Table of Content

- What is an AEC Industry?

- What’s the Importance of Fabrication to the AEC Industry?

- 5 Ways Fabrication Enhances Productivity in the AEC Industry

- Streamlined Project Timelines with Offsite Manufacturing

- Improved Quality and Precision through Prefabrication in Construction

- Scalable and Flexible Solutions with Modular Building Components

- Cost-Effective Competitive Construction Strategies

- Enhanced Safety and Site Efficiency

- Conclusion

What is an AEC Industry?

The AEC industry thrives on teamwork. Thanks to the teamwork of architects, engineers, and builders, we get the infrastructure we need every day. This includes homes, offices, roads, bridges, and public spaces.

Let’s take a look at their respective roles that shape the industry.

Architects

They begin the process with thoughtful designs that combine function and style. They create the layout and vision for each project.

Engineers

Ensure designs are safe, efficient, and structurally sound. They focus on systems, stability, and practical execution.

Construction Teams

They handle the building process, from managing building materials to coordinating labor and schedules.

What’s the Importance of Fabrication in the AEC Industry?

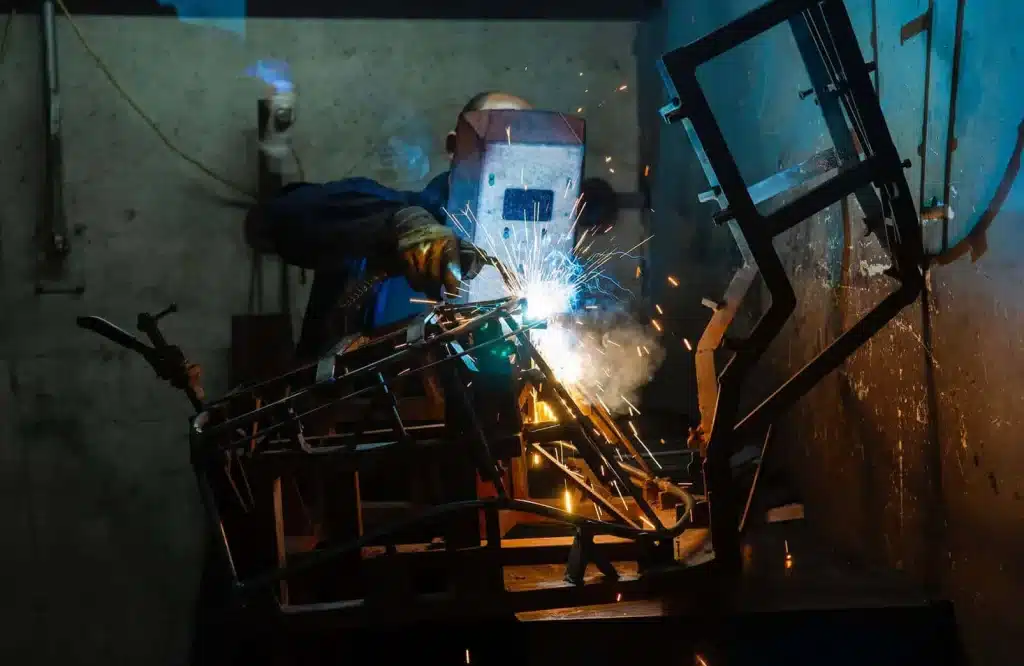

Fabrication is important in the AEC industry as it helps turn designs into real structures. This is done using pre-measured, pre-cut, and tested parts.

This process reduces errors, limits waste, and speeds up construction, giving companies an edge in today’s competitive market.

Fabrication in Architecture

Fabrication helps bring new designs to life. It uses advanced methods like digital modeling and CNC machining.

Fabrication in Construction

Effective fabrication processes streamline building timelines by shifting to offsite manufacturing of building components. With components fabricated in advance, projects can move forward more quickly once on-site work begins.

Fabrication in Engineering

Engineering benefits significantly from fabrication, as it enables engineers to create custom solutions tailored to complex challenges. By utilizing advanced materials and techniques, engineers can enhance functionality while adhering to safety standards.

Stay ahead in the AEC industry with Precision-Driven Fabrication

Modular. Scalable. Built for performance.

TOTC delivers customized fabrication services that streamline construction and boost project efficiency.

EXPLORE OUR FABRICATION SOLUTIONS5 Ways Fabrication Enhances Productivity in the AEC Industry

Modern methods like offsite manufacturing and prefabrication help AEC companies finish projects faster, safer, and cheaper.

Here are five ways fabrication improves productivity across the AEC industry:

1. Streamlined Project Timelines with Offsite Manufacturing

Offsite manufacturing means making building parts in a controlled place. These parts are then moved to the construction site for assembly.

This method prevents delays caused by bad weather, limited space, or on-site coordination issues.

By doing fabrication work and site preparation at the same time, projects will move faster. This helps teams meet deadlines and stay on schedule.

2. Improved Quality and Precision through Prefabrication in Construction

Prefabrication in construction is a way of building parts with precise measurements using advanced machines and quality checks. This accuracy lowers mistakes and reduces the need for rework on-site, which can cause expensive delays.

3. Scalable and Flexible Solutions with Modular Building Components

Using modular building components allows a general contractor in the Philippines to rapidly assemble structures while maintaining flexibility for design changes or future expansion.

Manufacturing these modular units offsite enables scalable construction that easily adapts to different project sizes.

Ultimately, this approach helps optimize labor and equipment, reducing downtime in manufacturing process and boosting workforce solutions.

Discover How TOTC Leads in Delivering Customized Fabrication Services

Learn more about our expertise by exploring our role as a leading provider in customized fabrication services driving innovation and efficiency in the AEC industry.

READ OUR LATEST CASE STUDY HERE

4. Cost-Effective Competitive Construction Strategies

Using fabrication-focused workflows helps cut costs by lowering labor hours and reducing material waste. These savings make companies more competitive when bidding on projects and boost profit margins.

By including fabrication early in planning, construction teams can apply strategies that boost daily productivity.

5. Enhanced Safety and Site Efficiency

Shifting the construction process to controlled fabrication facilities reduces clutter and hazards on the job site.

With fewer materials stored and processed on location, the risk of accidents declines, contributing to a safer work environment.

A study by the Construction Industry Institute (CII) shows that offsite fabrication and modular construction lower workplace accidents. This is done by moving dangerous tasks to controlled factory settings.

“Prefabrication enables the execution of hazardous tasks in controlled environments, significantly improving worker safety compared to traditional onsite construction methods”

This also limits onsite dangers such as falls, heavy equipment mishaps, and material handling injuries.

TOTC puts safety first by designing its fabrication services to minimize risks from the ground up. TOTC provides precise offsite manufacturing of modular building parts. This helps AEC companies lower onsite risks. It also increases productivity and ensures safety standards are met.

How Can TOTC’s Fabrication Services Help Your AEC Business Succeed?

If you’re an AEC company aiming to build smarter, faster, and more efficiently, TOTC is the partner you can trust. We engineered our fabrication solutions to keep your projects on schedule, under budget, and aligned with modern construction standards

From offsite manufacturing to precision-driven modular components, TOTC helps you streamline your workflow and enhance overall project productivity.

Conclusion

Understanding fabrication is important for businesses that want to boost productivity and stay competitive in today’s AEC industry. Using modern methods like offsite manufacturing and prefabrication helps in architecture, engineering, and construction. These methods reduce delays, lower costs, and minimize risks on site.

With modular components and efficient building strategies, construction teams can build faster and with greater accuracy. Choosing the right service partner for custom or full-scale fabrication leads to smarter, safer, and more sustainable construction.

To stay ahead, you must see fabrication not just as a process—but as a key to long-term success in the AEC industry.

Modular and scalable fabrication solutions are not just innovative they’re necessary for sustainable growth in architecture and construction. TOTC’s approach demonstrates leadership in the industry.